Easitrac - Turnout Operating Unit

Pending a proper instruction sheet, here are some quick series of sketches to illustrate how to make the turnout operating unit which moves the blades. And, at the bottom of the page, a video showing how to build it from Richard Benn

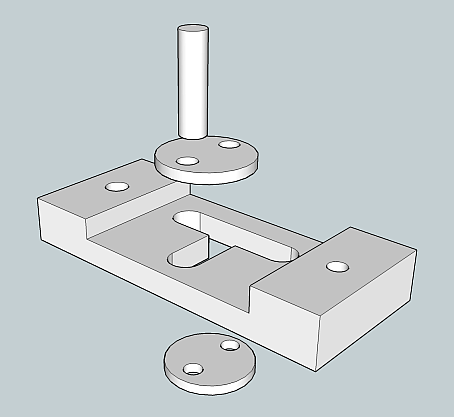

Solder small pin to the small discs, trapping the tie bar part between them,

but with enough slack to allow tie bar to rotate/slide between the discs.

Solder small pin to the small discs, trapping the tie bar part between them,

but with enough slack to allow tie bar to rotate/slide between the discs.

Solder the inner spindle to the discs. This creates a cam from the discs

and pins.

Solder the inner spindle to the discs. This creates a cam from the discs

and pins.

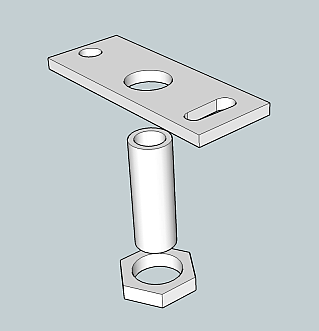

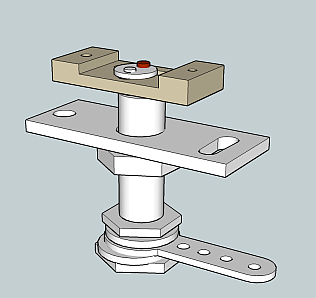

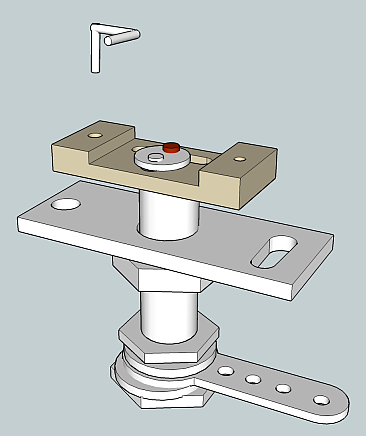

Assemble the below baseboard fixing plate, threaded tube and large locknut.

Assemble the below baseboard fixing plate, threaded tube and large locknut.

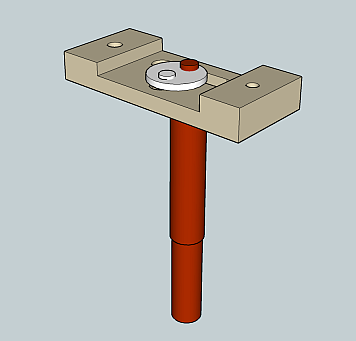

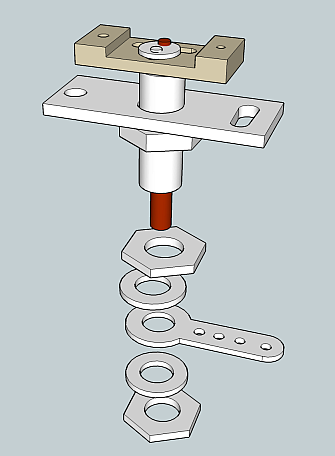

Slide tiebar/cam assembly into baseboard fixing tube, secure operating lever

with smaller nuts and washers as shown.

Slide tiebar/cam assembly into baseboard fixing tube, secure operating lever

with smaller nuts and washers as shown.

Assembled unit should look like this (probably neater as your washers will

be the right size!). Operating lower lever will cause the upper tie bar

to slide side to side (left to right in drawing).

Assembled unit should look like this (probably neater as your washers will

be the right size!). Operating lower lever will cause the upper tie bar

to slide side to side (left to right in drawing).

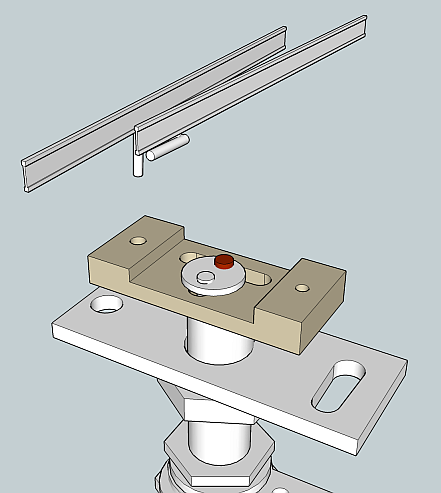

Bend up the blade fixing wires as shown, jig shown lower down the page (two

required, only one shown, they are handed).

Bend up the blade fixing wires as shown, jig shown lower down the page (two

required, only one shown, they are handed).

Fix blade (right rail in sketch) to operating wire, stock rail (left in

sketch) rests on horizontal of operating wire, thus ensuring blade remains

at correct height.

Fix blade (right rail in sketch) to operating wire, stock rail (left in

sketch) rests on horizontal of operating wire, thus ensuring blade remains

at correct height.

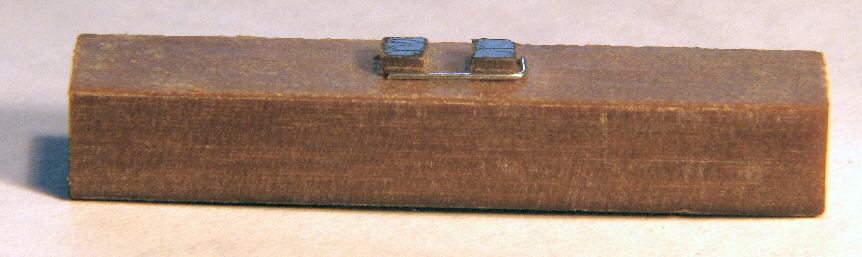

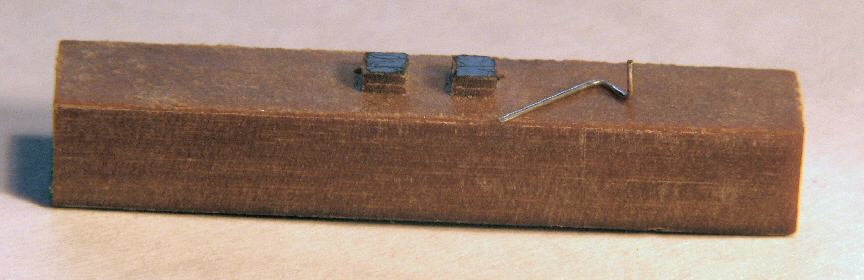

The TieBar wire bending jig produces the small piece of bent wire shown in the diagrams above.

A piece of 0.3mm wire is inserted into the jig, and bent around the raised

parts as shown. Tweaking in pliers to get 90 degree bends may be necessary.

Note the jig has two holes drilled, and can make LH and RH versions of the

wire.

Finished bent wire resting on top of jig. Solder one end alongside the blade

and fit the other end into the turnout operating unit.

Finally a video showing the assembly. The tie bar shown is a little wobbly, Richard subsequently re-assembled the upper section, making new support disc parts which removed the wobble. However, once installed on a layout, the wobble will be controlled by the baseboard and track, so its not of concern at this stage. Anyway, watch the video, it makes it all clear....